Opening the Power of Engines: A Comprehensive Guide to Efficiency and Effectiveness

Comprehending the intricate mechanics of engines is vital for both efficiency fanatics and daily motorists. The solutions might redefine our approach to engine efficiency and performance in means that are both informing and essential.

Understanding Engine Basics

What constitutes the fundamental mechanics of an engine? At its core, an engine is a machine designed to transform gas right into mechanical energy with a series of controlled surges or burning processes. The main components include the cylinder, piston, crankshaft, camshaft, and shutoffs. The cyndrical tube acts as the chamber where combustion occurs, while the piston relocates within the cyndrical tube to transform the energy from combustion right into straight movement (ford fiesta engine).

The crankshaft then transforms this straight activity right into rotational energy, which ultimately powers the car. The camshaft controls the opening and closing of the valves, managing the consumption of air and fuel and the expulsion of exhaust gases. Additionally, the engine depends on a carefully adjusted fuel-air blend, ignition system, and cooling system to ensure optimum efficiency and effectiveness.

Understanding engine basics additionally includes recognizing the value of engine cycles, such as the four-stroke cycle, that includes intake, compression, exhaust, and power strokes. Each stage is crucial in ensuring the engine operates smoothly and effectively. Proficiency of these basic auto mechanics lays the groundwork for exploring a lot more complicated engine dynamics and efficiency metrics, important for optimizing both power output and performance.

Trick Efficiency Metrics

Secret efficiency metrics are vital for reviewing an engine's efficiency and power result, providing useful understandings for both customers and suppliers. These metrics act as criteria for engine efficiency, permitting for informed decisions in style, production, and purchasing.

Among the primary metrics is horsepower, which quantifies the engine's ability to carry out work over time. Torque, determined in pound-feet, is one more vital statistics that shows the engine's rotational pressure, straight impacting acceleration and towing capacity. Fuel efficiency, generally measured in miles per gallon (MPG) or liters per 100 kilometers (L/100km), assesses how effectively the engine converts gas right into activity, affecting ecological factors to consider and functional expenses.

Additionally, thermal efficiency measures just how well an engine transforms fuel energy right into valuable job, exposing understandings into energy losses primarily via warmth. Discharge levels, including CO2 and NOx, are additionally crucial, reflecting the engine's environmental influence and conformity with governing requirements.

Tuning Methods for Performance

Tuning methods play a substantial duty in enhancing engine efficiency by optimizing performance metrics determined in earlier discussions (ford fiesta engine). Different techniques exist to adjust an engine, each adding to boosted gas Get More Info economic situation and lowered exhausts

One effective technique is adjusting the air-fuel proportion, ensuring the engine runs within the optimal burning regimen. A leaner combination can boost gas effectiveness, however it needs to be balanced to avoid misfires or engine knock. Furthermore, reprogramming the engine administration system can alter specifications such as ignition timing, which even more boosts performance while keeping power outcome.

One more important method involves changing the consumption and exhaust systems. Upgrading to high-performance air filters and exhaust headers can decrease back stress, promoting far better air flow. This allows the engine to take a breath more freely, leading to boosted combustion efficiency.

In addition, the execution of sophisticated adjusting devices, like dyno testing, gives exact data that makes it possible for targeted modifications. Consistently monitoring these efficiency metrics guarantees that adjusting efforts produce the preferred effectiveness end results. Collectively, these techniques not just boost engine performance however also add to lasting sustainability in engine operations.

Upkeep for Ideal Efficiency

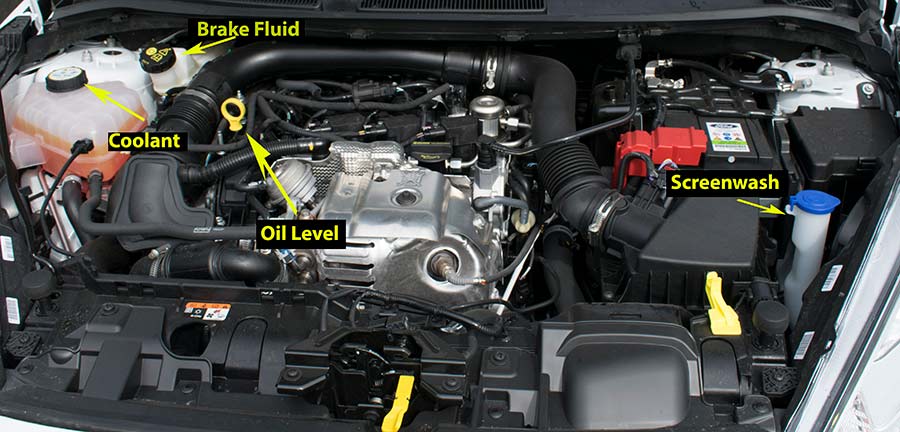

Routine engine upkeep is necessary for achieving optimum performance and longevity. A properly maintained engine not only runs efficiently yet also lessens the risk of expensive fixings and break downs. Trick components needing normal attention include oil, filters, belts, and ignition system.

Changing the engine oil at suggested periods is crucial, as oil lubricates relocating components and avoids overheating. In a similar way, replacing oil and air filters guarantees that impurities do not impair engine function. Ignoring these elements can bring about reduced efficiency and prospective engine damages.

In addition, examining and replacing used belts and tubes is vital to stop abrupt failings. Timing belts, in particular, ought to be replaced according to the maker's timetable to stay clear of catastrophic engine damage.

Spark plugs ought to also be checked and replaced as required, because they play a vital duty in ignition and gas performance.

Future Fads in Engine Modern Technology

Welcoming innovations in modern technology, the future of engine design is poised to transform performance and efficiency across various my explanation applications. Among one of the most substantial fads is the shift toward electrification. Hybrid and fully electrical powertrains are coming to be significantly conventional, using minimized exhausts and boosted gas effectiveness. This change is not just a necessity but a fad driven by regulative pressures and consumer need for lasting options.

Additionally, innovations in products science are bring about lighter, stronger parts that page improve engine efficiency while minimizing energy usage. Advanced production methods, such as 3D printing, permit the development of intricate geometries that enhance air movement and thermal administration, thus maximizing combustion procedures.

Furthermore, the integration of expert system and artificial intelligence is established to change engine diagnostics and performance adjusting. These innovations can analyze huge amounts of data in actual time, making it possible for predictive upkeep and tailored performance improvements.

Final Thought

To conclude, opening the power of engines calls for a complete understanding of their auto mechanics and efficiency metrics. Applying effective tuning methods and sticking to normal upkeep techniques considerably improve engine abilities. As the auto landscape evolves, embracing future trends in innovation, consisting of electrification and progressed production, will certainly be critical for maximizing performance and efficiency. This extensive technique not just advantages fanatics but also adds to sustainable services in the world of automotive engineering.

Furthermore, the engine counts on a meticulously calibrated fuel-air mixture, ignition system, and cooling system to guarantee optimum efficiency and performance.

Understanding engine essentials also entails acknowledging the significance of engine cycles, such as the four-stroke cycle, which consists of intake, compression, power, and exhaust strokes. Proficiency of these fundamental technicians lays the groundwork for discovering much more intricate engine dynamics and efficiency metrics, vital for optimizing both power outcome and performance.

Welcoming advancements in technology, the future of engine design is poised to transform performance and efficiency across various applications.